Stabilized Soil Mixing Plant

1. Brief Introduction

Stationary stabilized soil mixing plant is suitable for large scale continuous operation of the stable layer of highway construction. The aggregate, power and water adopt frequency conversion to control the rate of flow, which achieves high measuring accuracy and stability. The quantity of aggregate storage bins can be changed from four to six according to the needs of the project.

2. Process Material Application

1. Lime: raw lime or clinker (moisture between 10-15%, particle size shall be treated according to practical project request);

2. Soil (below 60mm, moisture no more than 10%);

3. Gravel (below 60mm, moisture no more than 10%);

4. Fly ash (moisture between 10-15%);

5. Bulk cement or bag cement.

3. Final Product

1. Cement stabilized gravel;

2. Lime stabilized base material;

3. Compressible concrete (must be stirred two times, the contract must indicate the use).

4. Main Configuration Of Such Plant

1. Aggregate Batching System: Aggregate hopper and Metering device

2. Powder feeding metering system: Powder silo and Metering equipment

3. Water system

4. Agitating device

5. Product conveyor

6. Storage device drive: pneumatic and air compressor

7. Electrical circuit system

8. Control system

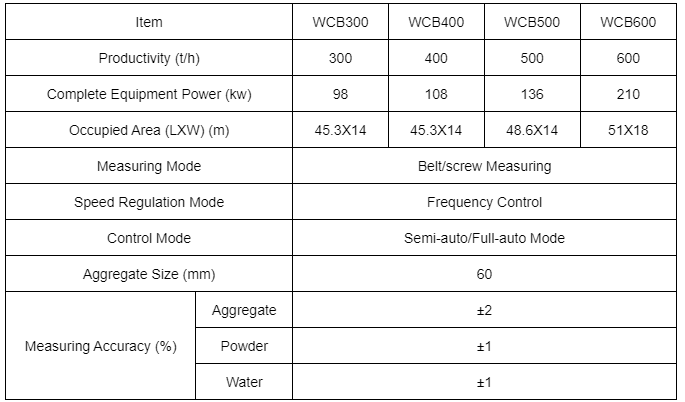

5. Main Technical Parameters

Any change of technical data shall not be advised additionally.

Copyright © 2023 All Rights Reserved.