Hopper Type Concrete Batching Plant

1. Brief Introduction:

This series of concrete batching plant adopts modular structure, it is specially designed for customers who need to change the construction site frequently. It is simple in installation, compact in structure, place saving and high automation. It is mainly used for bridge, building, water conservancy project, power and other infrastructure projects.

2. Main Characters:

1. Less funds possession

2. Less space occupation

3. Less equipment application

4. Accurate measurement of batching machine

5. High quality concrete producing

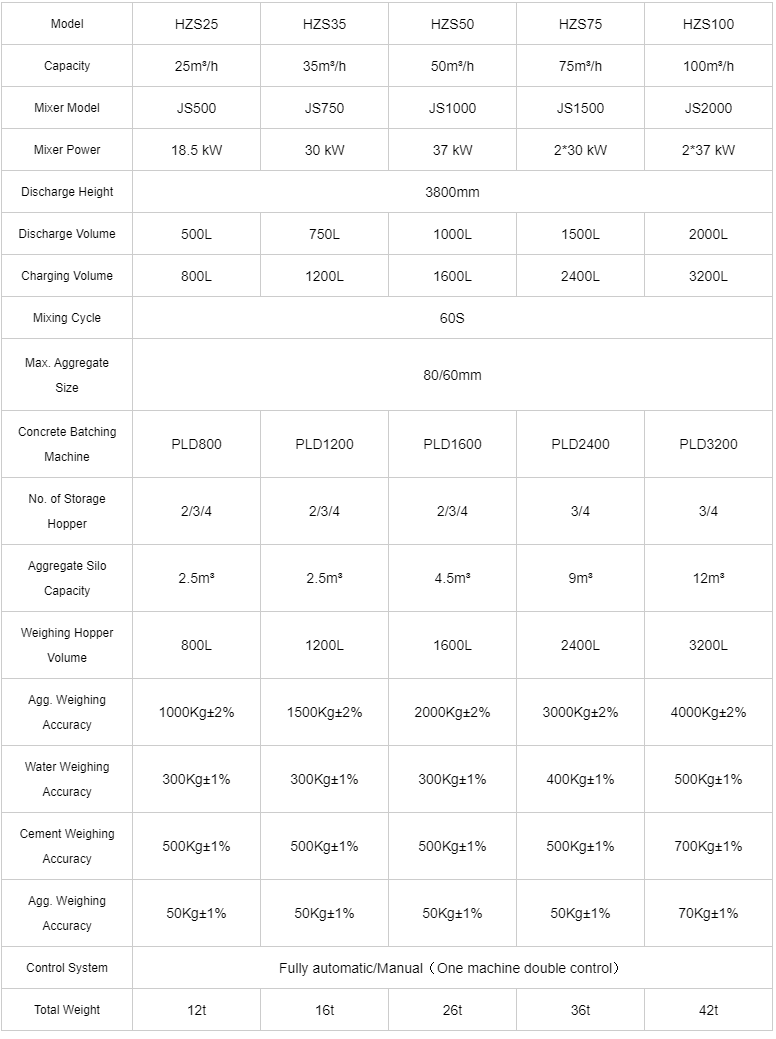

3. Parameters:

Any change of technical data shall not be advised additionally.

4. Hopper Type Concrete Batching Plant Features:

The mixing blade is made from high anti-abrasion alloy and its lifetime can reach 200000m3/times, no need to exchange always which lowed the cost.

The track of mixer is flexible designed, and can be sent into container directly which save the delivery cost.

High efficiency mixing motor with high protection level, it is designed according to F class insulation which guarantees the long lifetime and high reliability.

Adopt 12.5mm steel wire with max. tensile force 10T, which makes sure lifting hopper’s loading speed and security.

Lifting motor with brake and anti-bearing lock design to achieve safe running and low failure rate.

Weighing system adopts S-shaped sensor and three-point mounted weighing for fast weigh and high accuracy.

Support legs for mixer are made of national standard steel and are reinforced with inclined strut to lower machine vibration and stabilize plant operation.

Full-automatic control system with famous brand electrical components domestic and abroad (Schneider, Siemens, TENGEN, CHNT) and EVOC industrial personal computer to achieve full-automatic and manual operation, also with Chinese, English, Russian, Arabic.

Our aggregate batching system can carry out the batching work in a range of three to six kinds of aggregates including but not limited to sand, rocks, gravel, potash, fly ash and cement automatically.

Copyright © 2023 All Rights Reserved.